23L Microwave Oven Front Panel Frame Press Tool Stamping

• Product Name: Microwave Oven Front Panel Frame;

• Type: Side door;

• Product Capacity: 23L ;

• Product Material: SUS304;

• Material Thickness: 0.5mm;

• Product Size: 483*262*42(mm)

Stages of the Press Tool Stamp :

• Reasonable stages arrangement, less issues, less repair;

• Have made molds for over 90% sheet metal parts of Microwave Oven;

• Tool Type: Tandem tool;

• Tool Stages:3

• Press Tonnage: 160T

Tool Structure :

Hiparter has 20+ experiences in designing and manufacturing Stamping Tooling. We have a variety of microwave oven panel and other home appliances stamping tooling manufacturing process capabilities.

Stamping Tooling Manufacturing Capacity :

1)Stamping tooling machining equipment more than 28 sets

2)Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets

3)Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc.

4)Almost all the machining process completed in-house.

5)We can guarantee the quality and lead time.

Tools Processing :

Split tooling drawings, mark processing methods and control processing quality.

In order to ensure that each stamping tooling is qualified before out our factory, we have a strict quality control mechanisms. We will inspect each stamping tooling as the following ways.

1) Hardness tester

2) Chemical analysis

3) Digital Measuring Projector

4) Dynamic Balancing Tester

5) Universal testing machine & Coordinate-Detector for CNC machining

If there is any quality problems, we will take full responsibility.

Choose Hiparter, you will set your mind at rest!

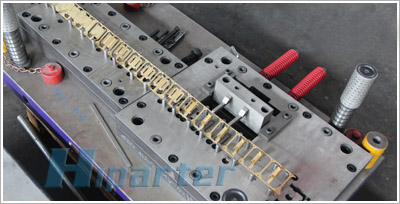

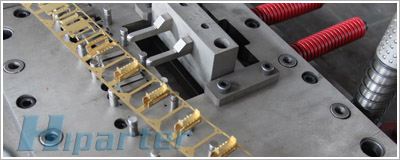

In-Die Riveting Progressive Die for Sheet Metal Hinge

Specification:

Part Name: Sheet Metal Hinge

Die Type: Progressive Die with Riveting

Product Material: SPCC;

Thickness: 2.0mm;

Die Materail:SKD11,Cr12mov, 45#;

Spare parts: MISUMI;

Die Size: 1370*570*510.5mm

Exported to:Russia

Engineering Highlights:

Equipped with :

Equipped with XYZ three-axis fine-tuning platform for automatic riveting equipment to precisely control rivet position.

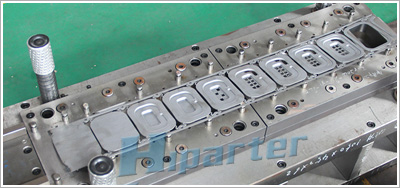

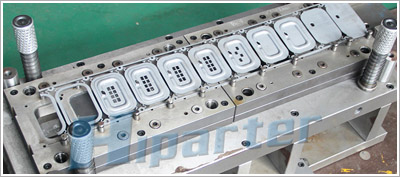

Qingdao Factory Microwave Oven Metal Press Panel Stamping Too

• With ISO9001:2008 certified;

• Good suggestions help customers improve there design.

• Tthere is an innovative, dedicated and experienced team;

• Rich experience, over 20 years in stamping dies;

• Reasonable die structures, less issues, less repair;

• Have made molds for over 90% sheet metal parts of Microwave Oven;

Product descriptions from the supplier :

Part Name: Microwave Oven Panel Stamping Tooling

Product Name:Microwave Oven Panel Stamping Tooling

Capabilities Applied/Processes:Tooling Design and Manufacturing, Testing, Batch production

Press for Mould trial:800 ton Press

Part Dimensions:Max Length: 3500mm;Max Width: 1500mm;Max Height: 550 mm

Tightest Tolerances:±.01mm

Die material:SKD11, SKH-9,D2, 1.2379

Material Finish:Tempering, Hardening, TD, PVC, Ti plating,

In Process Testing/Inspection Performed:CMM, Vision Projector, Callipers

Mould spare parts:PUNCH, MISUMI, FIBRO, DME, KALLER, DANLY, FESTO

Industry for Use:Washing machine, air conditioner, freezer, microwave oven, gas cooker, LED Tv etc.

Standards Met:2D(DXF,DWG),3D Drawing(STP, IGS)

Other Oven Stamping Tooling :

Hiparter has 20+ experiences in designing and manufacturing Stamping Tooling. We have a variety of microwave oven panel and other home appliances stamping tooling manufacturing process capabilities.

Stamping Tooling Manufacturing Capacity :

1)Stamping tooling machining equipment more than 28 sets

2)Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets

3)Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc.

4)Almost all the machining process completed in-house.

5)We can guarantee the quality and lead time.

Toolings Processing :

Split tooling drawings, mark processing methods and control processing quality.

In order to ensure that each stamping tooling is qualified before out our factory, we have a strict quality control mechanisms. We will inspect each stamping tooling as the following ways.

1) Hardness tester

2) Chemical analysis

3) Digital Measuring Projector

4) Dynamic Balancing Tester

5) Universal testing machine & Coordinate-Detector for CNC machining

If there is any quality problems, we will take full responsibility.

Customer acceptance tooling :

Welcome a trial order with your drawing! There are value-added services for you!

Multi-door Refrigerator sheet metal bracket progressive die

1.Tool type: Progressive stamping die;

2.Tool life:More than 500,000 shoots;

3.Machining Tolerance:0.02mm:

4.Tool Material:Mo-Cr steel, CR12MOV, CR12, 45#;

5.Standard parts: PUNCH, MISUMI Standard;

6.Design software:AutoCAD, Solidworks,UG;Product Used;

7.Process Procedure: Cutting, Piercing, Bending, Forming, etc.

Company Profile:

Located in Qingdao, Hiparter has more than 20 years experience in designing and manufacturing progressive stamping die,and we have a variety of die manufacturing process capabilities.We have developed a full-range progressive stamping die universal supply. In home appliance such as microwave oven, gas cooker, refrigerator, air conditioner, rice cooker, washing machine and water heater etc.

Refrigerator sheet metal bracket progressive die show:

1)Design according to the product drawings or samples provided by customers.

2)This die is designed to accommodate various process procedures, including blanking, cutting, piercing, bending and forming, allowing for versatility in manufacturing applications.

3)Provide customers inspection reports and samples for confirmation.

Our advantages:

1)4~6 weeks lead time

2)Update stamping die building progress to customer weekly, control project progress to ensure project schedule

3)Exported to over 30 counties

Our services:

1.In-time response by telephone or mails for questions;

2.In-time communication with you on the technical points.

3.In-time sending die machining progress and finishing schedule.

4.In-time die testing and samples delivery.

5.In-time die delivery.

Factory Progressive Microwave Oven Panel Stamping Tool

•Hiparter is a professional manufacturer of stage metal stamping tools and progressive stamping tools, committed to tool design, tool manufacturing and product production.

•In Hiparter, there is an innovative, dedicated and experienced team with more than 13 years experience.

Product descriptions from the supplier :

Part Name: Progressive Microwave Oven Panel Stamping Tool

Tool Type:Progressive Stamping Tool

Tool Material:SKH-9, DC53, SKD11,45#

Part Material:Stainless steel(SUS301, SUS304, SUS430 ) , etc.

Standard Part:MISUMI, PUNCH, FIBRO, DAYTON, DME, etc.

Manufacturing Machinery:Milling, Grinding, Boring, CNC, EDM, WEDM, Precision Flat Milling, Saw Machine

Press Machinery:45T~800T, Press machine, Punching machine, Forming machine

Inspection Machinery:CMM, Vision Projector, Micro-callipers, Laser Scanner, Alloy Analyzer

Forming Way:Punching, Blanking, Piercing, Bending, Forming, Deep Drawing, etc.

Tool Precision:High precision machining, minimum 0.02mm.

Lead Time:6 weeks for tool buidling, after the tool structure drawing confirmed.

Delivery:By sea or air, By air around 2-5 days, By sea around 10-30 days.

Other Oven Stamping Tool :

Hiparter has 20+ experiences in designing and manufacturing Stamping Tool. We have a variety of microwave oven panel and other home appliances stamping tool manufacturing process capabilities.

Stamping Tool Manufacturing Capacity :

1)Stamping tool machining equipment more than 28 sets

2)Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets

3)Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc.

4)Almost all the machining process completed in-house.

5)We can guarantee the quality and lead time.

Tools Processing :

Split tool drawings, mark processing methods and control processing quality.

In order to ensure that each stamping tool is qualified before out our factory, we have a strict quality control mechanisms. We will inspect each stamping tool as the following ways.

1) Hardness tester

2) Chemical analysis

3) Digital Measuring Projector

4) Dynamic Balancing Tester

5) Universal testing machine & Coordinate-Detector for CNC machining

If there is any quality problems, we will take full responsibility.

Customer acceptance tool :

Welcome a trial order with your drawing! There are value-added services for you!

Qingdao custom Steel Metal Progressive Microwave Oven Stamping Die

•Hiparter made the microwave oven cavity, bottom plate and back panel.

•The material strip shown in the left picture is for the cavity progressive die. For the cavity, the material width is 720mm. The problems were successfully overcome, such as the distortion of strip during drawing process, products broken, can’t cut off neatly etc. Thus we got praise from customer.

Product Description :

Part Name: Progressive Microwave Oven Stamping Die

Part Material: JSC270D;

Material Thickness: 2mm;

ISO9001:2008 by SGS;

Made in Qingdao, China

Forming, Blanking,Forming, Trimming;

HS Code: 820730090;

Related progressive die :

Hiparter has 20+ experiences in designing and manufacturing Stamping Die. We have a variety of microwave oven and other home appliances stamping die manufacturing process capabilities.

Stamping Die Manufacturing Capacity :

1)Stamping die machining equipment more than 28 sets

2)Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets

3)Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc.

4)Almost all the machining process completed in-house.

5)We can guarantee the quality and lead time.

Dies Processing :

Split dies drawings, mark processing methods and control processing quality.

In order to ensure that each stamping die is qualified before out our factory, we have a strict quality control mechanisms. We will inspect each stamping die as the following ways.

1) Hardness tester

2) Chemical analysis

3) Digital Measuring Projector

4) Dynamic Balancing Tester

5) Universal testing machine & Coordinate-Detector for CNC machining

If there is any quality problems, we will take full responsibility.

Customer acceptance die :

Welcome a trial order with your drawing! There are value-added services for you!

Refrigerator metal bracket progressive die

1)Product Used: Refrigerator bracket

2)Product Material: Galvanized sheet

3)Material Thickness: 1.4mm;

4)Die type: Progressive die

5)Stages Quantity: 13

6)Cavity: 1+1

7)Tool Material: SKD11,Cr12mov;

8)Machining equipments: WEDM-LS, CNC,EDM,etc.

9)Spare Parts: PUNCH,Misumi standard;

10)Die life: 1,000,000 shots;

11)Lead time: 50 days;

12)FOB Qingdao;

Related stamping dies:

Try/Test stamping dies:

We have about 20 sets of punching machines.

Before delivery the dies, we try them in our workshop conveniently,

so that we can guarantee the dies run smoothly before delivery them.

Sheet Metal Cable Clamp Progressive Stamping Die

1)Product Used: Porsche Cable Clamp

2)Product Material: HC260LA

3)Material Thickness: 1.5mm;

4)Die type: Progressive die;

5)Stages Quantity: 15

6)Cavity: 1

7)Tool Material: SKD11,Cr12mov;

8)Machining equipments: WEDM-LS, CNC,EDM,etc.

9)Spare Parts: PUNCH,Misumi standard;

10)Die life: 1,000,000 shots;

11)Quality cerficated: ISO 9001:2008;

12)Lead time: 50 days;

13)FOB Qingdao;

14)Payment: TT;

15)HS code: 8207300090

16)Delivery: By sea.

17)Exported to: UK

Related progressive die:

We have about 20 sets of punching machines.

Before delivery the dies, we try them in workshop to guarantee the dies can run smoothly.

Dies Processing:

Split dies drawings, mark processing methods and control processing quality.

Citroen 405ECS Motor Carbon Brush Holder Progressive Tool

Made in Qingdao,China.

Used in Citroen 405 ECS;

Part Material: Cuzn;

Material Thickness:0.6mm;

Stages Quantity:17;

Toold Material: SKD11,Cr12mov;

Spart Parts: PUNCH,Misumi standard;

FOB Qingdao;

Payment: TT;

Related progressive die:

In order to guarantee the precision of the sizes, we use 17 stages to realize it. There are sereral idle stages for maintainance when necessary.

Use sliders to curle the parts.

Advantages of service:

1. Rich experience;

2. Resonable die structure to save stamping die cost;

3. Quick-change system, you can repair or maintain the dies conveniently when the dies on press machine;

4. In-house for all the machining work;

5. One-stop service.

Automotive SPHC Metal Nozzle Progressive Die

Part Name:10HZ UPPER/LOWER NOZZLE

DTR for FCA;

Die Type: 2 Progressive Die+1 Singe Stage Die;

Shaping Mode: Punching Mold;

Product Material: SPHC;

Thickness:1.6mm;

Die Materail:SKD11,Cr12mov, 45#;

Spare parts: MISUMI;

ISO9001:2008;

Trial Sample Picture:

Related Progessive Die:

In order to improve the productivity, these parts are produced by progressive dies and single stage dies. The upper and lower part are in the same forming die to reshape the outside shape, and realize the sizes within tolerance.

Check And Acceptance:

Customer from MOBIS check the stamping dies on spot.

Welcome you visit Hiparter!

Find What You Want

Home Appliance Parts

Progressive Dies

Deep Drawing Dies

Tags

Latest Home Appliance Dies

-

Water Heater end Cover

Read 7270 times

Supply precision water heater end cover; Located in Qingdao, China; Rich experience since 2003; High precision: 0.02mm

Supply precision water heater end cover; Located in Qingdao, China; Rich experience since 2003; High precision: 0.02mm -

water heater stamping parts

Read 7523 times

Rich experience in making water heater stamping dies and water heater stamping parts. Have made kinds of stamping dies for…

Rich experience in making water heater stamping dies and water heater stamping parts. Have made kinds of stamping dies for… -

High End Washer Front Panel Punching Tool with Surface Treatment

Read 4359 times

1)Tool type: Stage Punching Tool 2)Product Material: Cold steel, Galvanized steel, Stainless steel, etc. 3)Die material: SKH-9, DC53, SKD11, Cr12Mov,…

1)Tool type: Stage Punching Tool 2)Product Material: Cold steel, Galvanized steel, Stainless steel, etc. 3)Die material: SKH-9, DC53, SKD11, Cr12Mov,… -

Microwave Oven Metal Case

Read 6870 times

This Microwave Oven Metal Case is made by progressive die, we improve the die stages and die structure to increase…

This Microwave Oven Metal Case is made by progressive die, we improve the die stages and die structure to increase…